The BLDC motor is dead. Long live the Brushless motor!

There is no such thing as a Brushless DC (BLDC) Motor. Rotating electric machines produce torque in one of two ways – field alignment and reluctance (saliency). In either case, a rotating magnetic field is required, and in a brushless motor this is generated from AC current in the stator. So any brushless motor is really an AC motor … brushless DC motors don’t actually exist!

The term BLDC motor originates from the fact that when an electronic controller is driving (commutating) the motor, when viewed from the DC terminals of the controller the system behaves like a traditional brushed DC motor – speed varies proportionally with applied DC voltage. Essentially the mechanical commutator (the part that uses the brushes) is replaced by an electronic controller with power transistors. There are various methods of modulating these transistors, the most common and simple method being referred to as “trapezoidal drive” (it’s also the lowest performance, but this is a subject for another blog). In all cases, however, the current produced by the controller and flowing through the stator windings of a BLDC motor is AC, not DC.

Brushless motors have enormous advantages over conventional brushed machines — the obvious one being that there are no brushes to wear out — but also speed, efficiency, weight, size, and reliability are greatly improved. The growth in applications and popularity of brushless motors has paralleled and been enabled by the tremendous advancements in power electronics and controls – the underlying technology needed to produce the “electronic commutator” (often referred to interchangeably as: drive, controller, electronic speed controller, inverter, etc).

As the world becomes increasingly electrified – propelled by relentless advancements in power electronics, controls, and energy storage technology — brushless motors will unquestionably play an even bigger role. Electric and Hybrid electric vehicles are becoming more competitive with conventional gasoline powered vehicles as energy storage technology (particularly lithium ion batteries) improves and becomes less expensive. Not only do electric vehicles use brushless motors for the main traction drive, but also for the accessory systems such as pumps for power steering and compressors for air conditioning, which used to be belt-driven from the engine. Even aircraft, such as the Boeing 787 Dreamliner, are becoming increasingly electric with fly-by-wire systems and electrically operated actuators replacing conventional hydraulics and other mechanical systems. Eventually, when the energy density of batteries gets good enough, electric propulsion may even become practical for aircraft — this in fact has already happened for small Unmanned Aircraft Systems (UAS).

MAGicALL is a world leader in the design and manufacture of high performance brushless machines (motors and generators) and power electronics. We make both permanent magnet (PM) and induction machines — operating at very low speeds up to well over 100,000 RPM — with unparalleled torque and power densities, specifically customized for your application. Contact us today and let us show you what’s possible!

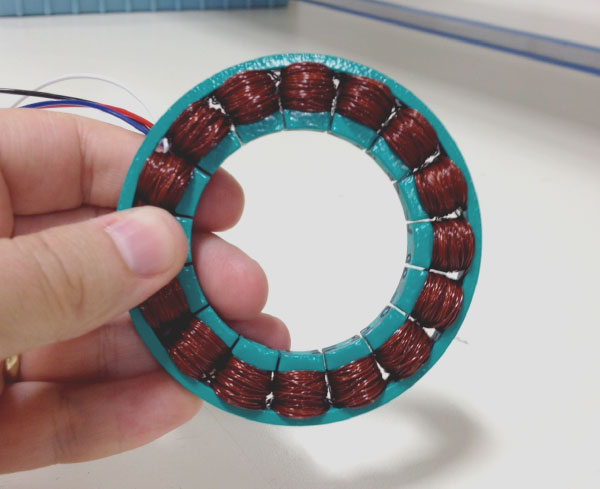

The stator of a BLDC motor. The stator currents are AC, not DC